Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Diameter: 0.016-5mm or customized

Material: 201,304,304L,316,316L or customized

Type: Flat Wire, Round Wire, Fine Wire, Fibre Wire, Yarn, Plated Wire

Standard: AISI, ASTM, JIS, DIN, EN, BS

Packaging: In Coil, On Spools, Customized Packaging

Lead Time: Stock or 3-10 days or according to quantity

Our Advantage:

Manufacturer/Supplier

Competitive Price

Minimum Order Quantity 1000KG

Free Test Samples

Quick Response Within 12 Hours

Quality Guaranteed By SGS

Comply With European and American Standards

Directly Supplied By Our Factory

Products Description

As a trusted stainless steel annealed wire manufacturer with over 40 years of experience, we operate complete stainless steel wire production lines to ensure consistent quality and high efficiency. Our annealed wire, made from premium materials such as 304, 304L, 316, and 316L, undergoes precise heat treatment to relieve internal stress and improve flexibility, ductility, and corrosion resistance. We offer factory-direct sales, customizable specifications, and reliable delivery. Every batch is strictly inspected for diameter, tensile strength, elongation, and surface quality, providing our customers with high-performance annealed stainless steel wire.

Annealed stainless steel wire is a type of high-ductility, soft stainless steel wire made from cold-drawn stainless steel wire through an annealing heat treatment process. It uses high-quality stainless steel wire (such as 304, 304L, 316, 316L, etc.) as raw material and eliminates internal stress generated during cold working through the annealing process. The annealing process involves heating the stainless steel wire to a high temperature, maintaining a constant temperature in a protective atmosphere, and then slowly cooling it to release internal stress and allow the crystal structure to reorganize. Compared to hard or semi-hard stainless steel wire, annealed stainless steel wire has lower hardness and higher elongation, making it easier to bend, wind, braid, knot, and undergo secondary forming processes.

● Material: Typically made from stainless steel grades such as 304, 304L, 316, or 316L, which offer excellent corrosion resistance and durability.

● Softness: The annealing process makes the wire softer and more pliable compared to its hard-drawn counterpart.

● Surface Finish: Usually has a smooth, bright finish, though it can also be supplied with a matte finish depending on the application.

● Corrosion Resistance: Retains the inherent corrosion-resistant properties of stainless steel, making it suitable for use in harsh environments.

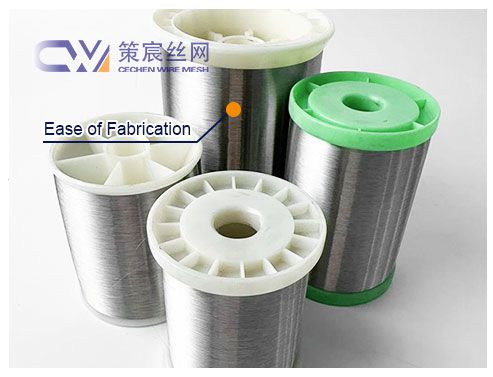

● Ease of Fabrication: The softness of the wire makes it easier to bend, cut, and shape without cracking or breaking.

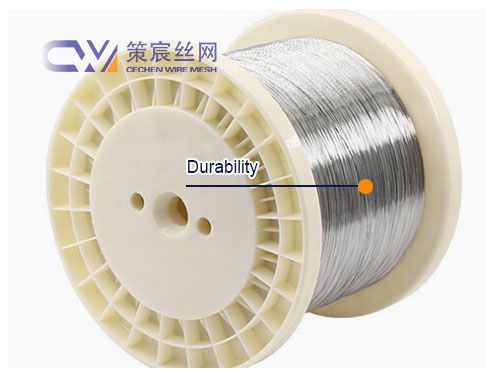

● Durability: Despite being soft, it retains the strength and corrosion resistance of stainless steel.

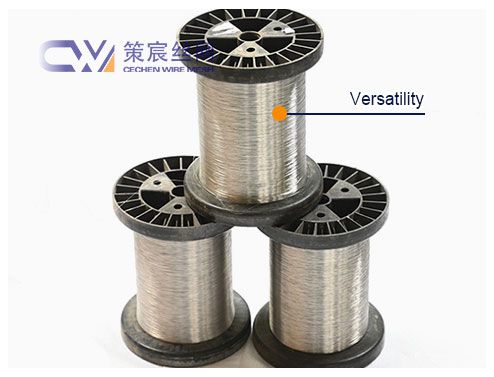

● Versatility: Suitable for a wide range of applications across various industries.

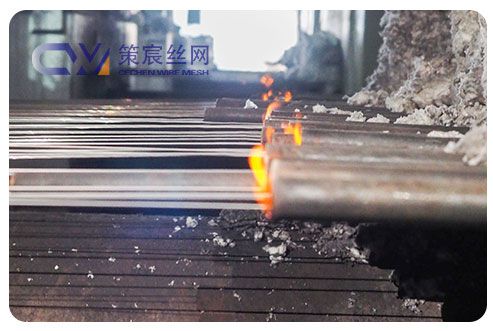

In the production process of annealed stainless steel wire, we first select high-quality stainless steel wire and pre-clean it to remove grease and impurities, ensuring a smooth and defect-free surface during heating. Then, the stainless steel wire is placed in a hydrogen-protected furnace or vacuum furnace and heated to the appropriate annealing temperature, causing the internal grains to recrystallize and completely release cold working stress. Afterwards, the stainless steel wire is uniformly held at a high temperature to completely reorganize and soften the grains, thereby improving ductility. Subsequently, slow cooling or controlled atmosphere cooling stabilizes the grains, completely releasing stress and keeping the stainless steel wire flexible while maintaining excellent corrosion resistance. After annealing, we straighten, wind, and surface clean the stainless steel wire, and rigorously test its diameter, flexibility, tensile properties, and surface quality to ensure that each batch of products meets high-quality standards, providing customers with directly processable flexible stainless steel wire.

Thanks to its excellent flexibility and ductility, our stainless steel annealed wire is ideal for bending, weaving, and forming in wire mesh, filters, and precision components. Its high corrosion resistance makes it suitable for industrial, marine, and outdoor applications, while the soft, easily processed wire is widely used in binding, packaging, and decorative projects. The combination of strength, durability, and workability ensures reliable performance across diverse industrial and commercial uses.

● Wire Mesh & Filter Manufacturing – for industrial, chemical, and food-grade filtration systems.

● Binding & Tie Wire – packaging, construction, and industrial fastening.

● Baling & Wrapping Wire – secure bundling of materials in logistics and manufacturing.

● Precision Components & Formed Parts – bent, coiled, or shaped wire for mechanical or engineering use.

● Jewelry, Crafting & Decorative Wire – flexible wire for art, design, and DIY projects.

● Marine, Automotive & Architectural Uses – applications requiring durability and corrosion resistance.

Our stainless steel annealed wire is available in a variety of standard and custom packaging options. Common packaging methods include coils and spools to meet different processing and application needs.

Each coil or spool is tightly wound and secured, then wrapped with plastic film or waterproof paper to prevent moisture, dust, and surface contamination. Export shipments are further packed into wooden crates or pallets for robust protection during long-distance transport and handling.

Our production workshop is equipped with 129 advanced wire drawing machines and 14 continuous annealing production lines, forming a complete stainless steel wire manufacturing system from wire drawing to annealing and finished product finishing. Relying on high-precision wire drawing equipment, we can ensure stable wire diameter dimensions, small errors, and high repeatability, meeting the stringent tolerance requirements of various applications.

With advanced equipment configuration and a standardized production management system, we can continuously provide customers with stainless steel annealed wire products that are precise in diameter, have stable mechanical properties, and high quality consistency, ensuring long-term stable supply and reliable quality.

As a professional manufacturer, we provide 100% quality guarantee for our stainless steel annealed wire. Every batch undergoes a strict quality inspection process to ensure consistent performance and reliability. Our testing procedures include:

● Diameter and Tolerance Check – ensuring wire thickness meets precise specifications.

● Tensile Strength & Elongation Test – verifying mechanical performance for reliable use.

● Flexibility and Bending Test – ensuring the wire can withstand bending, twisting, and forming without breaking.

● Surface Inspection – checking for defects, rust, or discoloration to guarantee smooth and clean wire.

Through these rigorous quality control steps, we ensure that every coil of stainless steel annealed wire delivered to our customers meets high international standards.

Our stainless steel annealed wire has passed stringent CE and SGS certifications, ensuring compliance with international quality standards. Each batch undergoes comprehensive testing, including tensile strength, elongation, diameter accuracy, flexibility, and surface quality, meeting multiple international standards including ASTM, AISI, DIN, EN, and GB. These certifications demonstrate our commitment to high-quality production, safety, and stability, giving our customers complete confidence in our products and production capabilities.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.

Related Products

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.