Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Material: 201, 202, 304, 304L, 316, 316L, 430

Wire Diameter: 0.02 mm – 0.5 mm or customizable

Type: fine wire, fibre wire

Weight/Spool: 1–20 kg or customizable

Packaging: Spool

Standards: AISI, ASTM, JIS, DIN, EN, BS

Delivery Time: In stock or 3-10 days, or depending on quantity

Our Advantage:

Free Test Samples

Quick Response Within 12 Hours

Quality Guaranteed By SGS

Comply With European and American Standards

Directly Supplied By Our Factory

Products Description

Stainless steel yarn refers to fine threads made by twisting or spinning stainless steel wire, used in the production of textiles, protective gloves, and composite materials. Unlike ordinary stainless steel wire, stainless steel yarn is flexible and lightweight, making it suitable for weaving or knitting. It combines the strength and corrosion resistance of stainless steel with the softness and flexibility of yarn, making it an ideal choice for applications requiring both durability and flexibility.

Stainless Steel Yarn is a high-strength, durable, and corrosion-resistant material widely used in specialized textiles. It is ideal for fabrics requiring cut resistance, wear resistance, anti-static properties, or electrical conductivity, including cut-resistant gloves, aprons, sleeves, corrosion-resistant gloves, uniforms, and other safety wear. Flexible yet strong, the yarn can withstand significant tension without breaking, making it suitable for harsh working conditions. It is also used in high-temperature and heat-resistant textiles for protective clothing for firefighters, welders, and foundry workers.

High Strength and Durability

● Made with high-quality stainless steel wire, it can withstand high tensile strength and long-term use without easily breaking.

High Corrosion Resistance

● The stainless steel material ensures that it maintains its performance in humid, chemical, or high-temperature environments.

Flexible and Weavable

● The yarn is flexible in form, easily woven into fabrics, braids, or composites while maintaining strength.

Cut and Abrasion Resistant

● Suitable for making protective gloves, abrasion-resistant clothing, industrial safety textiles, etc.

High Temperature and Heat Resistance

● Suitable for protective clothing, welding suits, and textiles for high-temperature working environments.

Antistatic and Conductive

● Can be woven into antistatic or conductive textiles, suitable for electronics manufacturing or flammable and explosive environments.

Our stainless steel yarn are available in fine wire and fiber wire types, including various grades such as 201, 202, 304, 316, and 430, with commonly used diameters of 0.035 mm, 0.04 mm, and 0.045 mm. They are particularly suitable for antistatic and conductive textiles, providing safe and reliable performance for industrial, protective, and special applications.

Stainless steel yarn is chemically stable and highly inert, meaning it will not produce adverse reactions in various applications. Therefore, stainless steel yarn can be used in combination with other materials. In textiles, fine stainless steel yarn can add a unique metallic sheen, providing visual appeal to fashion garments, accessories, or decorative pieces, so it is also used in architectural and decorative applications, such as safety barriers, facades, and interior design elements, where both aesthetics and safety are important.

● Protective Gloves: Cut-resistant and abrasion-resistant, protecting workers in metal processing, food processing, glass handling, and other industries.

● Aprons and Sleeves: Provide additional protection for high-risk or abrasion-prone environments.

● High-Temperature Protective Clothing: Suitable for firefighters, welders, foundry workers, and other workers operating in high-temperature environments.

● Antistatic Textiles: Functional fabrics that can be woven into electronics manufacturing or flammable and explosive environments.

● Conductive Textiles: Specialized textiles used for applications requiring static dissipation or conductivity.

● Industrial Safety Protective Fabrics: Used in industrial textile applications requiring high strength, durability, and abrasion resistance.

● Special Functional Textiles: For example, composite reinforcement, precision filtration, or other industrial applications.

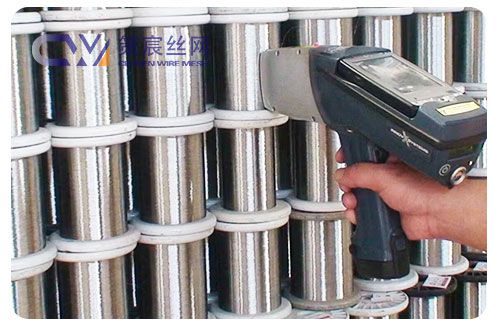

The common packaging method involves placing the spools on a pallet and wrapping them with plastic film to prevent moisture, dust, or surface damage during transportation and storage. This packaging method ensures that the yarn retains its flexibility, strength, and consistency, and is ready for direct use in textile or industrial production. Custom packaging is also available to meet specific customer needs.

Our stainless steel wire is produced in a modern, fully equipped workshop, ensuring precision and consistency at every stage. Each batch undergoes rigorous inspection procedures, including:

● Diameter inspection – ensuring uniform wire diameter.

● Surface inspection – detecting defects or surface irregularities.

● Material verification – confirming the stainless steel grade (e.g., 304L, 316L).

● Tensile strength testing – ensuring the yarn can withstand the required tension.

● Length and packaging verification – checking coil length and proper packaging (pallet, plastic film).

These steps guarantee that every spool of stainless steel yarn meets high standards of strength, flexibility, durability, and corrosion resistance.

Choosing our stainless steel yarn means choosing reliability, high quality, and stable performance. As a professional stainless steel wire manufacturer, we strictly control every step of the production process, from raw materials to finished yarn, ensuring uniform wire diameter, good flexibility, and excellent strength. Our products undergo rigorous testing and have obtained international certifications such as ISO, CE, and SGS, providing safe, durable, and reliable performance guarantees for industrial, protective, and functional textiles.

Our Advantages:

● Direct from Manufacturer: No middlemen, reasonable prices, and stable supply.

● Strict Quality Control: Testing of wire diameter, surface, material, tensile strength, and packaging ensures consistency in every batch.

● Complete Certifications: Complies with international quality standards such as ISO, CE, and SGS.

● Customizable Specifications: Supports different wire diameters, ply counts, and packaging methods.

● Reliable Performance: High strength, corrosion resistance, flexibility, and durability, suitable for various industrial and protective applications.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.

Related Products

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.