Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

When selecting stainless steel wire mesh for your project, the two most common grades are 304 and 316 stainless steel. While they may appear similar, these alloys differ significantly in composition, performance, and application suitability. This guide will help you understand the key differences between 304 vs 316 stainless steel wire mesh and provide selection advice tailored to your needs.

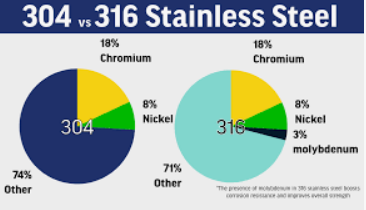

1. Chemical composition of 304 and 316 stainless steel wire mesh

2. Characteristics of 304 and 316 stainless steel wire mesh

3. Differences in mechanical properties between 304 stainless steel wire mesh and 316 stainless steel wire mesh

4. Applicable Scenes between 304 Stainless Steel Wire Mesh and 316 Stainless Steel Wire Mesh

5. Cost and economy of 304 stainless steel wire mesh and 316 stainless steel wire mesh

6. Conclusion

●304 Stainless Steel Wire Mesh:

Contains 18% chromium and 8% nickel, with no molybdenum. It offers a well-balanced composition that is suitable for most general-purpose uses.

●316 Stainless Steel Wire Mesh:

Composed of 16% chromium, 10% nickel, and 2–3% molybdenum. The addition of molybdenum provides enhanced resistance to corrosion, especially in harsh or marine environments.

| 304 Stainless Steel Mesh: | 316 Stainless Steel Mesh: |

●Excellent general corrosion resistance ●High surface smoothness and good weld ability ●Cost-effective and easy to process ●Not ideal for chloride-rich or acidic environments, where pitting and stress corrosion may occur | ●Superior resistance to chloride-induced corrosion (ideal for seawater, bleach, acidic chemicals) ●Higher durability in harsh chemical environments ●Preferred for long-term applications in coastal or chemical processing settings |

| Property | 304 Stainless Steel Mesh | 316 Stainless Steel Mesh |

| Yield Strength (MPa) | ~205 MPa at room temperature | ~210 MPa at room temperature |

| Tensile Strength | Moderate, suitable for general applications | Higher tensile strength at elevated temperatures (>500℃), maintains structural integrity |

| Heat Resistance | Short-term resistance: 800–1200℃ Long-term exposure above 650℃ may reduce strength | Continuous operation above 1000℃; better high-temp oxidation resistance due to molybdenum |

| Hardness | Slightly harder, less ductile | Slightly softer, but more ductile due to higher nickel content |

| Wear Resistance | Relies on dense oxide film from chromium for abrasion protection | Molybdenum strengthens grain boundaries; superior resistance in acidic/saline media |

| Ductility & Processability | High ductility; easy to weave, weld, punch; ideal for complex mesh designs | Slightly higher work hardening; needs careful processing but better long-term durability |

| 304 Stainless Steel Wire Mesh – Cost-Effective and Versatile | 316 Stainless Steel Wire Mesh – Built for Harsh Environments |

●Indoor structures, window screens, dry food processing ●Freshwater filtration, non-aggressive gas or air screening ●Great for projects with low corrosion exposure and budget sensitivity | ●Seawater filtration, ship components, coastal architecture ●Acidic or chemical filtration, such as pickling or electroplating ●High-temperature filtration, including oil refining and boiler systems ●Medical devices requiring strict sterilization resistance |

304 Stainless Steel Wire Mesh: Lower material cost,suitable for general or short-term projects

316 Stainless Steel Wire Mesh: Higher upfront cost due to molybdenum and nickel, but more durable and longer-lasting in corrosive or high-temperature conditions

Selection Tip:

For standard environments (e.g., freshwater, indoor air),304 stainless steel mesh offers great value.

In aggressive environments (e.g., marine, industrial chemicals), 316 stainless steel mesh reduces maintenance costs and downtime in the long run.

6. Conclusion

Choose 304 Stainless Steel Wire Mesh if you need a reliable, cost-effective material for general-purpose filtration, food-grade screening, or indoor applications.

Choose 316 Stainless Steel Wire Mesh when working in highly corrosive, salt-rich, or high-temperature environments, especially for chemical processing, marine applications, and medical-grade filtration.

Need Help Choosing the Right Stainless Steel Wire Mesh?

As a professional wire mesh manufacturer, we offer both 304 and 316 stainless steel mesh in various sizes and weaving types. Contact us to get a free consultation or explore our product catalog.

Rencent News

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.