Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

We often say that basically all types of stainless steel wire mesh have good high temperature resistance and corrosion resistance. So what are the specific high temperature resistant wire meshes? What temperature can it withstand? What are the most common scenarios for it to be used? This article will give you detailed answers and help you choose the most suitable high temperature resistant wire mesh.

Table of Contents

● 304/304L stainless steel wire mesh

● Inconel wire mesh

● Hastelloy wire mesh

● Nickel-chromium alloy mesh

● Molybdenum wire mesh

● Tungsten wire mesh

● Tantalum wire mesh

一、What is Stainless Steel High-Temperature Resistant Wire Mesh

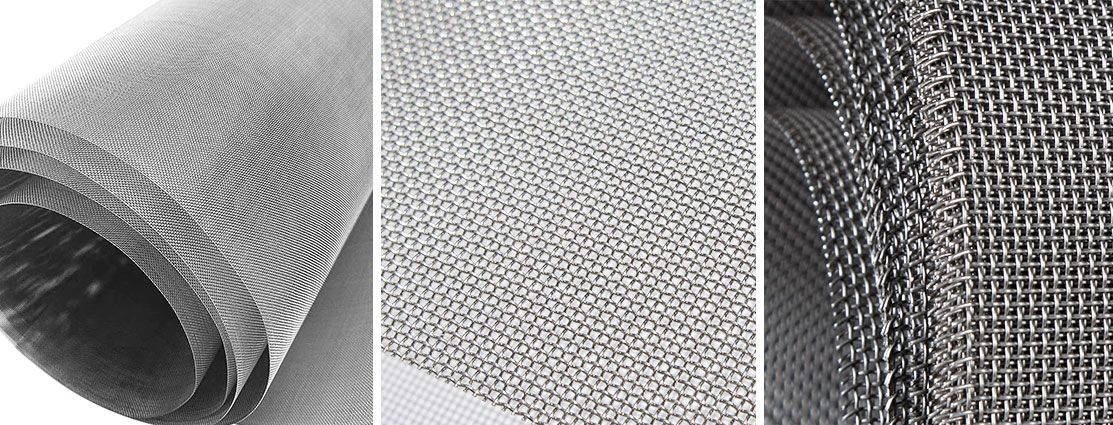

High-temperature resistant stainless steel wire mesh is a specialized metal mesh designed for extreme heat and corrosive environments. It is woven from heat-resistant stainless steel alloy wires and engineered to maintain structural integrity, tensile strength, and anti-corrosion performance at sustained temperatures ranging from 500°C to 1200°C. This makes it ideal for industrial filtration, reactor protection, and thermal insulation under harsh thermal and chemical conditions.

二、Common High-Temperature Mesh Materials and Their Performance

● Operating temperature: -196°C to 870°C

● Features: Affordable, widely used in food processing, medium-temperature filtration, and general industrial environments.

304/304L is the most common stainless steel wire mesh. It can be used continuously in an environment of -196℃~600℃, and the maximum operating temperature does not exceed 870℃. It is often used in medium-temperature environments such as food processing filtration and industrial filtration.

Inconel Wire Mesh (Nickel-Based Alloys)

● Inconel 600: -100°C to 1150°C

● Inconel 601: -100°C to 1200°C

● Applications: Furnace support mesh, jet engine insulation, chemical reactors, nuclear filtration, and submarine components due to its superb oxidation resistance and strength at high temps.

Inconel mesh is an alloy mesh with excellent high-temperature resistance. Inconel 600 can be used continuously in an environment of -100℃~1050℃, and the maximum operating temperature can reach 1150℃. The operating temperature of Inconel 601 is between -100℃~1150℃, and the maximum operating temperature can reach 1200℃. Due to its excellent high temperature resistance, Inconel nickel alloy mesh is often used for support mesh of high temperature furnaces, thermal insulation mesh of turbine engines and jet engines of aerospace equipment, high temperature catalytic reaction beds of chemicals, high temperature filtration protection mesh of nuclear reactors, and filter mesh of submarine facilities.

● Temp range: -50°C to 1175°C

● Key properties: High resistance to oxidation and acidic corrosion.

● Used in: Combustion chambers, flue gas filters, pharmaceutical catalyst supports.

Hastelloy wire mesh can be used continuously in the range of -50℃~1150℃, and the maximum operating temperature can reach 1175℃. It has strong anti-oxidation and corrosion properties, and is often used in high temperature flue gas filters, combustion chamber fireproof nets, pharmaceutical catalyst carriers, etc.

● Temp range: 200°C to 1250°C

● Known for: Excellent air resistance at high temperatures.

● Applications include: Electric heating elements, heat treatment mesh, glass melt filtration, aerospace insulation.

The temperature resistance range of nickel-chromium alloy mesh is 200~1200℃, and the maximum operating temperature can reach 1250℃. At this temperature, nickel-chromium alloy mesh can be used for a long time in the air. Therefore, nickel-chromium alloy wire is a special material for electric heating wire. Nickel-chromium alloy mesh is also often used as resistance heating wire mesh, high-temperature support mesh for heat treatment process, high-temperature insulation mesh for aerospace industry, high-temperature glass liquid filtration support mesh, high-temperature reactor filter mesh under oxidizing atmosphere, etc. due to its excellent high-temperature resistance.

Ultra-high temperature wire mesh (special alloy)

For example, molybdenum wire mesh, tungsten wire mesh and tantalum wire mesh have ultra-high high temperature resistance (molybdenum wire mesh 600~1700℃, tungsten wire mesh 800~2600℃, tantalum wire mesh 600~1500℃), but they are unstable in air and need to be used in a vacuum or inert gas environment. They are suitable for high temperature heating in a vacuum furnace environment.

三、Challenges of High-Temperature Environment to Materials

● High-temperature oxidation and corrosion: At high temperatures, metals react with media such as oxygen, sulfur, and chlorine to form oxide layers or corrosion products (such as FeO, FeS) on the surface, resulting in material loss and loose structure.

● Limitations of ordinary materials: The oxidation rate of carbon steel rises sharply above 500℃, the surface oxide scale peels off, and the service life is less than 100 hours.

● Typical scenarios

Sulfur-containing flue gas in petrochemical industry (sulfur corrosion above 650℃).

Chloride corrosion in waste incinerator (HCl gas + high temperature)

● Creep and Strength Reduction

Creep definition: The material undergoes slow plastic deformation under high temperature and continuous stress (such as long-term heat sagging of boiler pipes).

Data comparison: The tensile strength of 304 stainless steel drops to 40% of room temperature at 800℃, while 310S can still maintain more than 60%.

Notice: The creep rate of carbon steel at 600℃ is 5~10 times that of 310S stainless steel.

四、Core Performance Advantages of Stainless Steel High-Temp Mesh

● Thermal Resistance: Operates reliably at 500–1200°C, and endures brief spikes higher.

● Mechanical Strength Retention: Maintains >80% of tensile strength at high temperatures.

● Example: 310S retains >60% at 1000°C.

● Anti-Oxidation: Chromium content (e.g., 25% Cr in 310S) forms a Cr₂O₃ protective layer, preventing further oxidation.

● Structural Stability: Mesh deformation <3% at high temperatures with proper weaving (e.g., 50 mesh, 1.5mm wire).

● Molten Metal Resistance: Used in molten aluminum filtration (700°C) with surface treatments to extend mesh life 2–3x.

五、Typical Application Scenarios and Cases

| Industry | Use Case | Operating Temp |

| Petrochemical | Reactor protection, catalyst bed filtration | 600–900°C |

| Power Generation | Boiler burner screens, nuclear filtration mesh | 700–1100°C |

| Metallurgy | Molten aluminum/zinc filtration, furnace belts | 800–1200°C |

| Environmental | Waste incineration flue gas filtering | 500–800°C |

六、Selection Guide for High Temperature Wire Mesh

| Material | Max Temp | Key Traits |

| 304/316 | ≤ 500°C | Cost-effective, good oxidation resistance |

| 310S | ≤ 1100°C | High Cr/Ni, excellent for oxidation/sulfur environments |

| 314 / 253MA | ≤ 1200°C | Enhanced by rare earth for oxidizing conditions |

| Inconel (601/625) | ≤ 1200°C | Nickel-based, high creep resistance, ideal for aerospace/nuclear |

Mesh Structure Considerations:

Weave Types: Plain, twill, or dense weave depending on filtration accuracy vs. strength

| Mesh Type | Features | Applications |

| Coarse (5–50 mesh) | High tensile strength, lower filtration accuracy | Molten metal filtration, burner screens |

| Fine (100–400 mesh) | High filtration precision (down to 20μm), lower tensile strength | High-temp gas/dust filtration, catalyst beds |

Wire Size Tips: Use 1.0–2.0mm for high strength; 0.1–0.5mm for high precision

七、Get A Quote or Sample

Looking for high-temperature stainless steel wire mesh for industrial, energy, or environmental use?

Whether you need bulk orders, custom mesh specs, or engineering support, contact us now to get a free quote or sample for testing.

[Contact Our Team Today] or [Request Technical Datasheet]

八、Why Choose Hebei Cechen New Material Co., Ltd.?

At Hebei Cechen New Material Co., Ltd., we specialise in high-performance wire mesh solutions for thermal filtration, metallurgical processing, aerospace shielding, and catalytic support systems.

Our advantages include:

Customisation for temperatures up to 1250°C

ISO-certified production & third-party material testing

Support for low MOQ trial orders

Fast delivery & professional engineering support

Need a quote or sample?

Let us help you select the right high-temperature wire mesh based on your operating environment, mechanical stress, and filtration precision.

九、FAQ – Frequently Asked Questions

Q1: What mesh size should I choose for high-temperature gas filtration?

A: For fine particle filtration, select 100–300 mesh with 0.2–0.5mm wire diameter. Choose Inconel or 310S for strength and corrosion resistance at >800°C.

Q2: Can stainless steel mesh be reused after exposure to high temperature?

A: Yes, if there is no structural deformation or oxide flaking. For environments >1000°C, use alloys like 310S or Inconel for better reusability.

Q3: What’s the lead time for custom high-temperature mesh orders?

A: Lead time varies by material and structure. Standard stainless mesh ships in 3–5 days; Inconel/Hastelloy may take 10–15 days due to alloy processing.

Q4: Does wire mesh require surface treatment for molten metal filtration?

A: Yes. For example, when filtering molten aluminum, aluminum oxide surface treatment prevents erosion and extends service life 2–3×.

十、Industry Trends: Why The Demand For High-Temperature Wire Mesh Is Growing

In recent years, global industries have witnessed a rising demand for high-temperature stainless steel wire mesh due to:

● Stricter Emission Regulations: Industries such as waste-to-energy, steel plants, and coal power are upgrading to high-temperature filtration systems to meet air pollution control mandates.

● Energy Transition Projects: Hydrogen energy, battery production, and green metallurgy require extreme-temperature resistant materials for filtration and support.

● Aerospace & Defense Expansion: With the growth of space exploration and jet propulsion technology, Inconel and Hastelloy meshes are increasingly used in thermal shielding and reactive gas filtration.

Forecast:

The global industrial wire mesh market for high-temperature applications is expected to grow at CAGR 5.6% through 2030, led by Asia-Pacific manufacturing upgrades.

Rencent News

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.