Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Stainless Steel Knitted Wire Mesh

Stainless steel knitted mesh is manufactured using a knitting process where the mesh is formed from a series of interlocking loops. The original stainless steel knitted mesh is flattened when complete production, but it can be made into ginning knitted mesh by machine according to customers' requirements.

Stainless steel knitted wire mesh can be made of round wires or flat wires. The round wires is the most commonly used type and the flat wire knitted mesh is commonly used in special applications according to customers' requirements.

Leading stainless steel knitted wire mesh manufacturer, we specialize in producing high-quality mesh solutions tailored for industrial filtration, shielding, and separation applications. With advanced knitting machines and strict quality control, we offer customized specifications to meet the diverse needs of industries including petrochemical, automotive, electronics, and environmental protection. Whether you require mesh rolls, compressed mesh pads, or demister components, we provide cost-effective OEM/ODM services with fast delivery and global shipping.

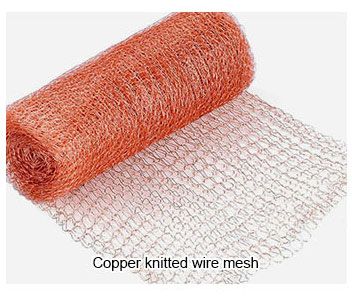

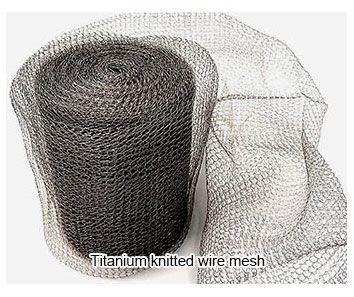

Knitted wire mesh is available in various materials to meet different industrial needs.

● Stainless steel (304, 316, 321) is the most widely used, offering excellent strength and corrosion resistance for filtration, demisting.

● Copper provides superior electrical conductivity, ideal for EMI/RFI protection.

● Brass offers both corrosion resistance and decorative appeal, used in chemical and design applications.

● Phosphor bronze is valued for its fatigue resistance and is suitable for marine and electronic filtration.

● Monel, a nickel-copper alloy, excels in harsh chemical and saltwater environments.

● Titanium is lightweight, corrosion-resistant, and heat-tolerant, making it ideal for aerospace and medical industries.

The efficiency, longevity, and suitability of knitted wire mesh in different environments depend heavily on both the chosen material and construction method. To address diverse application demands, we provide a wide selection of knitted mesh options, each engineered with specific materials and fabrication processes to deliver optimal performance in targeted industrial uses.

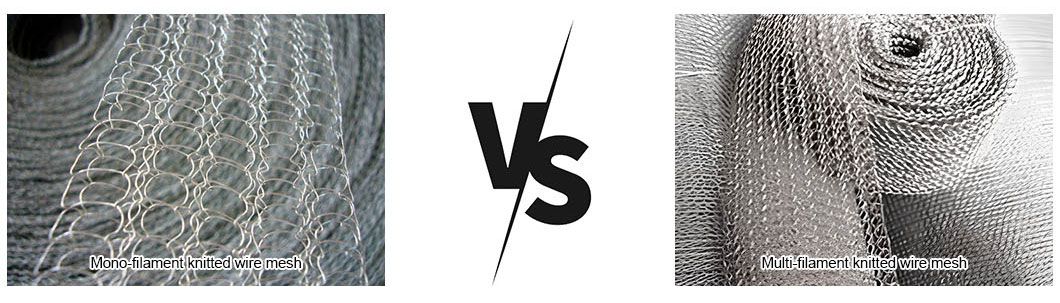

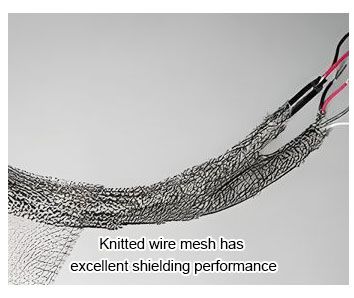

Mono-filament knitted wire mesh is made using a single strand of metal wire, forming a lightweight, flexible, and uniform mesh structure. It offers excellent elasticity and is easy to compress, shape, or roll. This type is ideal for applications such as mist eliminators, EMI shielding, and light-duty filtration where precision and flexibility are required.

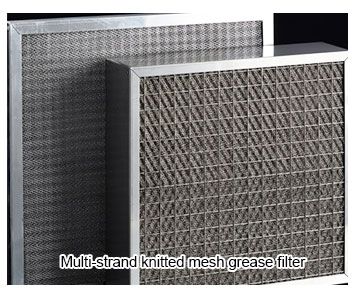

Multi-strand knitted wire mesh, on the other hand, is produced using multiple strands of wire twisted or bundled together before knitting. This results in a thicker, more robust mesh with greater strength and load-bearing capacity. Multi-strand wire mesh is especially suitable for heavy-duty uses such as gas-liquid separation, noise absorption, and high-pressure filtration environments.

Both types can be customized in terms of material, wire diameter, mesh density, and shape to meet specific industrial needs.

Knitted wire mesh can be manufactured in various structural forms to suit different industrial applications. The structure directly affects its flexibility, strength, surface area, and performance.

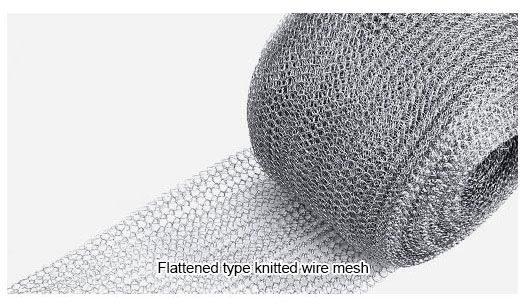

Flattened Knitted Wire Mesh

This is the most basic form of knitted wire mesh—produced in a flat, continuous ribbon-like structure. It is flexible, easy to handle, and widely used in rolls or cut-to-size sheets for general filtration, shielding, or insulation.

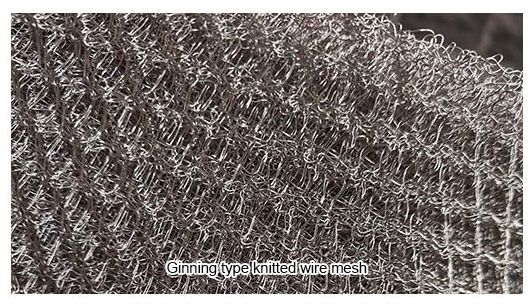

Ginning Knitted Wire Mesh

In this form, the mesh is processed with ginning type, which increase the surface area and allow for better flow and separation performance. It's commonly used in demister pads and structured packing systems.

Compressed Knitted Wire Mesh

Compressed knitted mesh is formed by pressing flat knitted mesh into various shapes such as discs, rings, cylinders, or blocks. This increases its density and stability, making it ideal for applications like mist eliminators, gas-liquid separators, and vibration dampers.

Multi-layer Knitted Wire Mesh

Multiple layers of knitted mesh are stacked or laminated to enhance filtration efficiency, strength, and thermal or acoustic performance. Multi-layered structures are often used in heavy-duty filtration, soundproofing, or exhaust system components.

| Specification of round wire stainless steel knitted mesh | ||||

| Wire Diameter (mm) | Width (mm) | Number of Stitches Per cm on Length | Number of Stitches Per cm Across Lay Flat | |

| Fine Mesh | 0.08 – 0.18 | 6 - 300 | 3.5 | 4.4 |

| Medium-fine Mesh | 0.16 | 40 - 600 | 2.4 | 3.5 |

| Standard Mesh | 0.18 - 0.35 | 30 - 1000 | 1.6 | 1.9 |

| Coarse Mesh | 0.25 - 0.40 | 30 - 1000 | 1.6 | 0.74 |

| Super Coarse Mesh | 0.4 - 0.5 | 100 - 350 | 0.5 | 0.5 |

| Specification of flat wire stainless steel knitted mesh | |||||

| Items | Wire Diameter (mm) | Mesh Opening/ Loop Size (mm) | Number of Needles | Maximum Width (mm) | Minimum Width (mm) |

| SSK-36 | 0.1 × 0.3 | 2 × 4 | 36 | 60 | 55 |

| SSK-34 | 0.1 × 0.3 | 4.5 × 4 2.5 × 4 | 34 | 150 | 100 |

| SSK-40 | 0.1 × 0.4 | 4.5 × 5.5 2.5 × 5.5 | 40 | 150 | 120 |

| SSK-56 | 0.1 × 0.4 | 4 × 3.5 2.5 × 3.5 | 56 | 205 | 180 |

| SSK-65 | 0.1 × 0.4 | 4 × 4 3 × 4 | 65 | 260 | 240 |

| SSK-94 | 0.2 × 0.4 | 5.2 × 3.5 3 × 3.5 | 94 | 420 | 380 |

| SSK-102 | 0.2 × 0.4 | 7.5 × 5 5 × 5 | 102 | 565 | 490 |

| SSK-128 | 0.2 × 0.5 | 5 × 4 2.5 × 4 | 128 | 560 | 470 |

| Note: Knitted mesh length can be customized according to customers' requirements. | |||||

● Corrosion Resistance: Stainless steel mesh is highly resistant to rust, oxidation, and other forms of corrosion, which makes it suitable for both indoor and outdoor applications.

● High Strength & Durability: Stainless steel's inherent strength ensures that the mesh can withstand mechanical stresses and wear.

● Flexibility: The knitting process allows the mesh to be flexible, unlike woven wire mesh, which is more rigid. This flexibility can be useful for applications requiring shaping or conforming to a particular surface.

● High-Temperature Resistance: Stainless steel can withstand extreme temperatures without losing its strength or structure.

● Non-Toxic and Safe: Stainless steel is non-toxic, making it suitable for applications in food processing, pharmaceuticals, and other sensitive industries.

● Filtration: Stainless steel knitted mesh is used in air, liquid, and gas filtration systems, such as in exhaust systems, chemical filtration, and even coffee filters.

● Seals and Gaskets: Its flexibility and resistance to heat make it ideal for creating seals and gaskets that prevent leaks in mechanical systems.

● Protective Mesh: Used in various industries for protective mesh around machinery or as a shield against debris.

● Heat Shields: It can be used in high-temperature environments as a heat shield or protective layer due to its resistance to extreme temperatures.

● Biomedical: Used for surgical meshes, filters, and other medical devices where high precision and safety are paramount.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.

Products Categories

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.