Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Wire Mesh

Cechen is a professional wire mesh manufacturer with 39 years of manufacturing experience. The factory is located in Anping County, Hebei Province, China's famous "Hometown of Wire Mesh". We are always committed to providing high-quality, multi-material and multi-specification wire mesh products, including stainless steel mesh, nickel mesh, titanium mesh, monel wire mesh, inconel wire mesh, hastelloy wire mesh, copper wire mesh, epoxy wire mesh, galvanized iron wire mesh, welded wire mesh, aluminum wire mesh, molybdenum wire mesh, zirconium wire mesh, tungsten wire mesh, tantalum wire mesh, etc., which are widely used in petroleum, chemical, construction, mining, food, medicine, aerospace and other fields.

As an wire mesh industry leader, we not only focus on the production of wire mesh and other products, but also provide a variety of Deep Processing Services such as Slitting, Laser Cutting, Punching, Edging, Forming, Welding, Sintering, Pleating, etc. to meet the personalized needs of various industrial applications.

With advanced production technology, strict quality control system and rich industry experience, our wire mesh products are deeply trusted by customers around the world for their excellent performance, reliable quality and excellent corrosion resistance, and are exported to Europe, America, Southeast Asia, the Middle East, South America and other countries and regions.

Please leave us a message to tell us your needs, and we will contact you within 2 hours! Whether you have customization requests or simply want to learn more about our products, our team is happy to offer you professional advice and a fast quotation.

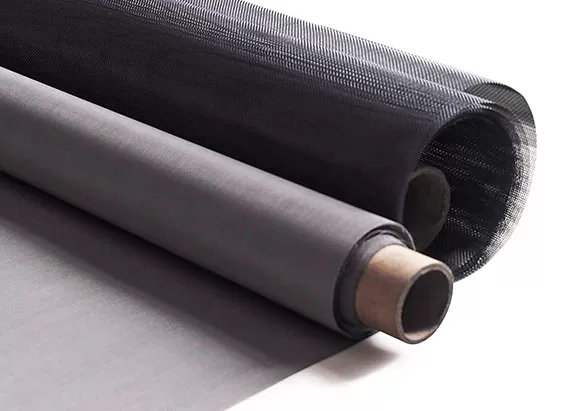

Stainless Steel Woven Mesh

Stainless steel wire mesh is a versatile material made from stainless steel wires woven or welded together to form a grid or mesh pattern. It is widely used in various industries due to its durability, corrosion resistance, and strength. People have different names according to its weaving methods and uses, such as: square mesh, plain wire cloth, twill dutch mesh, crimped mesh, welded wire mesh etc.

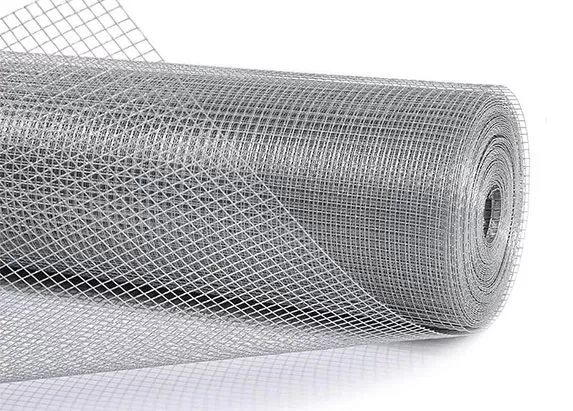

Stainless Steel Welded Mesh

Stainless steel welded wire mesh is a type of metal mesh product with uniform mesh openings, typically square or rectangular. Our stainless steel welded wire mesh uses high-quality stainless steel wire as raw material, undergoing precision straightening and automatic spot welding. The welds are strong, the mesh openings are uniform, the overall structure is stable, and it possesses excellent corrosion resistance and service life. It is widely used in building cladding, industrial protection, equipment isolation, filter support, aquaculture fencing, traffic protection, and special engineering structures.

Types: Stainless Steel Welded Wire Mesh Rolls/Sheets/Panels/Customization

Materials: Common stainless steel materials such as 201/304/316, and other custom stainless steel materials (such as 304L, 316L, 321, 310S, etc.)

As a professional stainless steel welded wire mesh manufacturer, we support full customization of parameters such as wire diameter, mesh size, mesh width, mesh length, weld strength, tolerance range, and packaging method. We can organize production according to ASTM, EN, ISO, and other standards to meet the technical specifications of different countries and industries.

Nickel Wire Mesh

Nickel Wire Mesh:

Nickel wire mesh is a metal wire mesh made of high-purity nickel wire. The materials of nickel wire mesh include N2, N4, N6, N8, NI200, NI201, etc. The most commonly used nickel wire mesh materials are N4 and N6. Different meshes, wire diameters and weaving methods can be customized according to different usage requirements.

● Material: Nickel

● Mesh: 1 mesh - 800 mesh

● Wire Diameter: 0.1mm - 2.0mm

● Width: 0.5m-1.5m and customized

● Length: 10m-100m customized

● Weaving Method: plain weave, twill weave

Nickel wire mesh is known for its excellent corrosion resistance, high temperature stability and good electrical conductivity. It has high electrical conductivity, thermal conductivity and ductility, heat resistance and wear resistance. Nickel wire mesh is often used in various industrial applications, including filtration, battery electrodes, EMI/RFI shielding and chemical processing.

Titanium Wire Mesh

Titanium Wire Mesh:

Titanium mesh is a mesh material made of titanium wire through weaving, welding and other processes. Titanium mesh has excellent corrosion resistance, strength, high temperature resistance and good biocompatibility, and is widely used in many fields such as chemical industry, aviation, medical, marine and water treatment. Due to the special properties of titanium, titanium mesh shows unique advantages in many environments that require corrosion resistance, high temperature resistance and wear resistance.

Titanium mesh can be divided into titanium woven mesh and titanium welded mesh according to different production processes. Different manufacturing processes give titanium mesh different characteristics and are suitable for different applications.

Alloy Wire Mesh

Alloy wire mesh is made of Inconel, Monel, Hastelloy, titanium alloy or other special metals interwoven or welded. It combines the characteristics of multiple metals to achieve excellent performance. Compared with standard wire mesh made of a single metal such as stainless steel or aluminum, alloy wire mesh has enhanced properties such as corrosion resistance, high strength and high temperature resistance. Alloy wire mesh is widely used in industries that require durability and high performance under gradient conditions.

Monels are typically known for their corrosion resistance (in both fresh and saltwater environments) and high strength, as well as their good low- and medium-temperature...

Inconel alloys are well-suited for use in extreme environments, including high-temperature and corrosive conditions. They are strong, ductile, and creep- and oxidation-resista...

Hastelloy is an ultra-low carbon type, Ni, Mo, Cr series nickel-based, corrosion-resistant, Hastelloy has good corrosion resistance and thermal stability and is mostly used in...

Copper Wire Mesh

Copper mesh is a mesh product made of high-quality copper wire through weaving, welding and other processes. Copper mesh has a variety of specifications and weaving methods, the most common ones are plain weave, twill weave, etc. In addition, copper mesh is also divided into brass mesh, copper mesh, and phosphor bronze mesh. They are all metal meshes made of copper-based alloys.

Because copper has good corrosion resistance, conductivity and beautiful appearance, copper mesh is not only practical, but also can enhance the appearance value of the product.

Red copper is pure copper, also known as red copper, which has good electrical and thermal conductivity, excellent plasticity, and is easy to process by hot pressing and cold pressing.

Brass wire mesh is a type of woven or knitted mesh made from brass wires, commonly used in a variety of applications due to its combination of strength, corrosion resistance....

Phosphor bronze wire mesh is applied to sieving and filtering granules, filtering liquid and gas, filter discs, craft papermaking, EMF/RFI shielding, faraday cages...

Special Material Wire Mesh

Special material wire mesh refers to wire mesh made of metal or alloy materials with special properties such as aluminum, tungsten, zirconium, tantalum, molybdenum, etc. These wire meshes have excellent high temperature resistance, corrosion resistance, wear resistance, oxidation resistance and other characteristics, and are widely used in chemical, aerospace, electronics, electrical, protection and other fields. According to the different materials and production processes used, special material wire mesh is mainly divided into the following categories.

Metal wire mesh can be made of many types of materials, each of which has unique properties and is suitable for different applications. We can produce a variety of metal types of mesh, which type are you interested in?

Galvanized Wire Mesh

Galvanized Wire Mesh:

Galvanized wire mesh is made from steel or iron wire that is coated with a layer of zinc through a hot-dip or electro-galvanizing process. The zinc coating acts as a protective barrier against corrosion, making galvanized wire mesh highly resistant to rust and suitable for both indoor and outdoor applications. Galvanized wire mesh is a versatile and durable material used in a wide variety of industrial, agricultural and residential applications.

We offer galvanized wire mesh in a variety of colors including blue, silver and gold. The materials used in our products are mild steel wire and galvanized wire, ensuring durability and reliability.

Iron Wire Mesh

Iron Wire Mesh:

Iron Wire Mesh refers to a grid-like structure made of iron or steel wire, which is woven, welded or stretched to form a durable and versatile material. Iron mesh is divided into woven wire mesh, welded wire mesh, galvanized wire mesh, PVC coated wire mesh, etc.

Iron Wire Mesh is commonly used in various applications due to its moderate price, high strength, wide application, durability, and ability to provide ventilation, filtration or safety protection.

Epoxy Coated Wire Mesh

Epoxy Coated Wire Mesh:

Epoxy-coated wire mesh is primarily woven from average steel wire as well as covered with top-notch epoxy powder with an electrostatic spraying process to make this material immune to corrosion and also acid.

This mesh is widely used in a variety of applications across different industries due to its combination of strength, flexibility, and protective qualities. The epoxy coating not only provides a barrier against environmental factors but also improves the aesthetic appearance of the wire mesh.

The most common epoxy wire mesh spec is 18 x 14 x 0.007 (18 in warp direction, 14 in shute direction, both wires with 0.007” diameter).

Wire Mesh (also known as metal wire mesh, woven wire mesh, wire mesh cloth) is a high-performance mesh material made of metal wire through weaving, welding and other processes, with excellent versatility and practicality. According to the different needs of customers, we provide wire mesh products of various materials, including high-performance metals and alloy materials such as stainless steel, nickel, titanium, monel, inconel, hastelloy, copper, aluminum, molybdenum, zirconium, tungsten, tantalum, etc.

| Wire Mesh Type | Material | Mesh Range (Mesh) | Wire Diameter Range (mm) | Aperture Range (mm) | Open Area (%) | Weaving Method | Typical Applications |

| Stainless Steel Mesh | 304, 304L, 316L, 316, etc | 1 – 2800 | 0.03 – 1.2 | 0.03 – 5.0 | 26 – 74 | Plain, Twill, Dutch Weave | Filtration, Protection, Construction, Food Processing |

| Nickel Mesh | Ni200, Ni201, etc | 10 – 200 | 0.03 – 0.5 | 0.05 – 2.0 | 30 – 65 | Plain, Dutch Weave | Chemical, Corrosion Resistant Filtration |

| Titanium Mesh | Gr1, Gr2, etc | 10 – 150 | 0.05 – 0.6 | 0.1 – 3.0 | 30 – 65 | Plain, Twill | Aerospace, High-Temperature Filtration |

| Monel Mesh | Monel 400, etc | 10 – 200 | 0.05 – 0.6 | 0.1 – 2.0 | 30 – 60 | Plain, Twill | Marine, Corrosion Resistant Applications |

| Inconel Mesh | Inconel 600, 625, etc | 10 – 300 | 0.03 – 0.5 | 0.05 – 1.5 | 28 – 65 | Plain, Dutch Weave | High Temperature, High Pressure, Chemical |

| Hastelloy Mesh | Hastelloy C-22, C-276, etc | 10 – 200 | 0.03 – 0.5 | 0.05 – 1.5 | 28 – 60 | Plain, Dutch Weave | Chemical, Corrosion Resistant Filtration |

| Copper Mesh | Pure Copper, etc | 4 – 200 | 0.05 – 1.2 | 0.05 – 5.0 | 30 – 75 | Plain, Twill | EMI Shielding, Decoration, Filtration |

| Epoxy Mesh | Low Carbon Steel + Epoxy Coating, etc | 2 – 60 | 0.3 – 1.5 | 0.3 – 10.0 | 40 – 75 | Welded or Woven | Corrosion Protection, Industrial Filtration |

| Galvanized Iron Wire Mesh | Low Carbon Steel + Galvanized, etc | 1 – 100 | 0.5 – 2.0 | 0.5 – 20.0 | 30 – 70 | Welded, Woven | Construction Protection, Fencing |

| Welded Mesh | Stainless Steel, Galvanized Steel Wire, etc | 1/4” – 2” | 0.5 – 2.5 | Varies by mesh size | 30 – 70 | Welded | Construction, Farming, Fencing |

| Aluminum Mesh | Pure Aluminum and Aluminum Alloys, etc | 4 – 100 | 0.2 – 1.2 | 0.2 – 5.0 | 40 – 75 | Plain, Expanded Mesh | Filtration, Decoration, Light Industry |

| Molybdenum Mesh | Mo ≥ 99.95% | 10 – 150 | 0.05 – 0.3 | 0.05 – 1.0 | 30 – 65 | Plain | High Temperature, Corrosive Environment |

| Zirconium Mesh | Zr702 | 10 – 100 | 0.05 – 0.4 | 0.05 – 2.0 | 30 – 65 | Plain | Nuclear Industry, Chemical |

| Tungsten Mesh | W ≥ 99.95% | 10 – 200 | 0.03 – 0.5 | 0.03 – 1.0 | 30 – 65 | Plain | High Temperature, Corrosive Environment |

| Tantalum Mesh | Ta ≥ 99.95% | 10 – 120 | 0.03 – 0.4 | 0.03 – 1.0 | 30 – 65 | Plain | Chemical, Corrosion Resistant Filtration |

We have a wide range of wire mesh products, including woven mesh, welded mesh, expanded metal mesh and other processes to meet diverse industrial applications and customization needs. As an important industrial material, wire mesh is widely used in many fields such as building reinforcement, mine screening, agricultural protection, liquid and gas filtration, safety protection and food processing.

Cechen is a leading China wire mesh manufacturer, specializing in the production of high-quality woven and welded wire mesh products for global markets. Our factory is ISO 9001:2015 certified, and all mesh products comply with international standards such as ASTM E2016, CE, and RoHS, ensuring reliable performance and export-level quality.

Certifications: ISO 9001, CE, SGS, Material Test Certificate (EN 10204 / 3.1)

To meet the demands of various specifications and production volumes, we operate three independently managed production workshops, each focused on different categories and mesh sizes. These workshops are led by a team of senior production supervisors, each with over 20 years of hands-on experience in wire mesh weaving and welding. Their deep industry knowledge ensures every product is manufactured with precision, efficiency, and consistency.

With Cechen, you're never left waiting. Our experienced customer service team is committed to delivering fast, effective communication and real solutions — every inquiry receives a reply within 12 hours, ensuring you get the support you need, when you need it.

Get in touch with Cechen now for professional advice, custom solutions, and competitive quotes.

Industrial Wire Mesh Supplier

As a professional industrial wire mesh supplier, we are committed to providing high-quality, customized wire mesh product solutions to customers in various industries. Whether you need industrial wire mesh for filtration, screening, protection or structural support, we can meet your diverse needs. Our products cover a variety of materials such as stainless steel wire mesh, nickel wire mesh, titanium wire mesh, etc., and support a variety of weaving and welding processes to ensure that the products perform well in corrosion resistance, strength and service life. With advanced production equipment and a strict quality management system (ISO 9001 certification), we ensure that each batch of wire mesh meets customer standards and industry requirements. No matter which industry you come from, choosing us as an industrial wire mesh supplier will help your business develop efficiently.

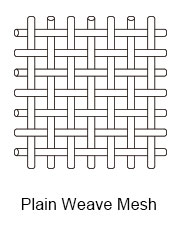

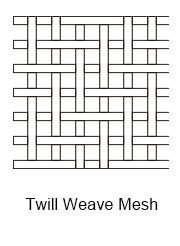

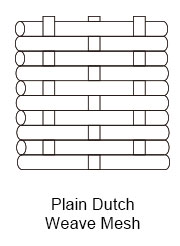

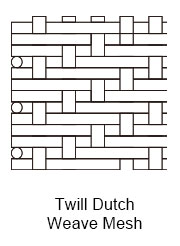

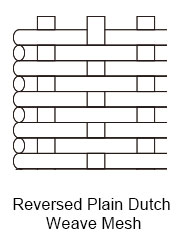

The weaving process of the wire mesh is the core link that determines its quality, strength and application performance. Unlike ordinary wire mesh manufacturers, we have deep experience in weaving technology and have mature weaving processes such as plain weave, twill weave and Dutch weave. As a professional woven wire mesh manufacturer, Cechen has mature weaving technology and advanced weaving equipment to meet a variety of needs from coarse mesh to high-precision filtration. During the entire weaving process, we combine digital tension control, automatic detection and manual sampling to strictly control key parameters such as mesh number, aperture, wire diameter, opening rate, etc. to ensure high product precision, stable performance and long service life. With high-precision equipment and an experienced technical team, we provide customers with accurate, stable and durable high-quality products.

| Weaving Method | Structure Features | Typical Applications |

| Plain Weave | Warp and weft wires cross alternately, uniform mesh opening, flat surface. | General screening, filtration, decoration. |

| Twill Weave | Each weft wire passes over and under two warp wires, denser and thicker structure. | Precision filtration, heavy-duty operating conditions. |

| Dutch Weave | Coarse warp wires and dense fine weft wires, creating very small openings. | Liquid or gas fine filtration in chemical and pharmaceutical industries. |

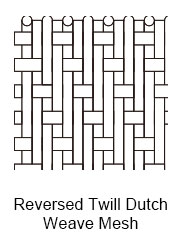

| Reverse Dutch Weave | Opposite to Dutch weave, with dense warp and coarse weft wires, suitable for pressure filtration. | Oil filtration, gas purification, backwash systems. |

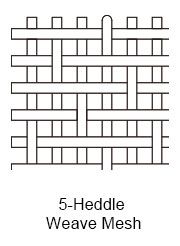

| Five-heddle Weave | Multi-point contact structure, strong mesh surface, better pressure resistance. | High-strength support, aerospace and high-pressure systems. |

| Crimped | It is made of pre-bent metal wire interwoven up and down, and has the advantages of stable structure, high strength and uniform mesh. | Mining and stone screening, construction and decoration, industrial filtration and support layer, safety protection |

● Over 39 Years of Industry Experience

● Diverse Materials & Customization Capabilities

● Precision Weaving & Advanced Equipment

● Strict Quality Assurance with Full Certification

● Global Export Focus & Fast Delivery

● Dedicated Customer Support

● MOQ: 50 rolls (custom size available)

● Delivery Time: 7–15 working days, depending on order quantity

● Payment Terms: T/T (30% deposit, 70% before shipment); L/C negotiable

● Packaging: Water-proof paper + plastic film + wooden case or pallet, suitable for export

Contact us today for a quick quote, sample, or technical support. Let Cechen help you find the best metal mesh solution for your application.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.