Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Industrial Filter Screen

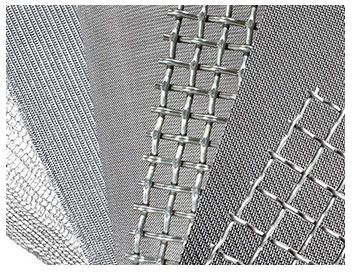

Metal woven mesh is an indispensable core component of modern industrial filtration systems. It not only efficiently intercepts particles but also ensures the stability of the entire process, flow control, pressure drop management, and long-term operating costs. With increasing demands for filtration accuracy, corrosion resistance, and system continuity in industries such as industrial, environmental, and water treatment, metal mesh has become the structural foundation of industrial filtration systems.

Metal mesh is widely used in various filtration systems, from industrial liquid filters and water treatment plants to critical process stages in automotive fuel systems. Its high strength, high temperature resistance, corrosion resistance, and stable precision make it an ideal choice for equipment requiring efficient separation, purification, and protection.

Key Advantages:

● High-Precision Filtration: Stable and uniform pore size enables filtration from coarse to micron-level fine filtration, ensuring the purity of liquids, gases, or powders.

● High Durability: Materials such as stainless steel and galvanized steel can withstand high temperatures, high pressures, and chemical corrosion, making them suitable for various harsh operating conditions.

● Washable and Reusable: The metal mesh can be reused multiple times through rinsing, ultrasonic cleaning, or chemical cleaning, reducing long-term operating costs.

● Customizable Design: Pore size, wire diameter, material type, and structural form can be customized according to process requirements to meet the needs of different industrial applications.

We design and manufacture high-quality wire mesh for filtration. Our filtration mesh products are precision-engineered to meet the specific demands of industrial processes, providing reliable performance for liquids, gases, and solids. With customizable mesh sizes, materials, and constructions, our solutions are tailored to deliver optimal flow, filtration accuracy, and long-term durability across industries such as manufacturing, food and beverage, pharmaceuticals, mining, and chemical processing.

We offer filters in a variety of materials, weave patterns, and pore sizes to ensure you receive products that perfectly meet your specifications.

The performance, lifespan, and application effectiveness of industrial filter meshes largely depend on the selected material. Commonly used materials include stainless steel, copper and copper alloys, nickel-based alloys, titanium, and sintered metal mesh. Different materials offer advantages in corrosion resistance, high-temperature resistance, mechanical strength, and washability, making them suitable for various industrial conditions.

● Stainless steel mesh: Excellent overall performance, corrosion-resistant, high-temperature resistant, and high-pressure resistant, suitable for most industrial liquid and gas filtration;

● Copper/Bronze/Brass Mesh: Good wear resistance, suitable for low-corrosion and oil filtration;

● Nickel-based mesh: Suitable for high-temperature, highly corrosive environments, such as strong acid liquids in chemical processes;

● Titanium mesh: Resistant to strong acids and seawater corrosion, suitable for special operating conditions;

● Aluminum Mesh: Lightweight yet durable, ideal for specialized machinery and lightweight industrial processes;

Material selection must be considered in conjunction with the characteristics of the process medium, temperature and pressure conditions, filtration accuracy, and service life requirements to achieve efficient, stable, and durable long-term operation of the filter. Appropriate material matching is a prerequisite for industrial filters to perform their key functions, and it is also an important factor in ensuring the economy and process safety of the system.

Industrial filter meshes can be categorized into woven wire mesh, perforated plates, sintered metal mesh, and multi-layer composite mesh, based on their structure and process requirements. Different types offer advantages in filtration accuracy, flow capacity, mechanical strength, and cleaning/maintenance methods, making them suitable for various industrial conditions.

Suitable for high-precision filtration, fine powder and liquid filtration

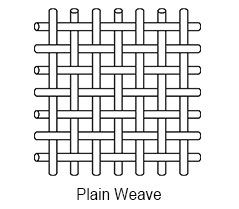

● Plain Weave: Stable pore size, suitable for general filtration.

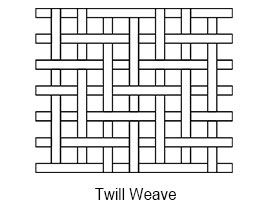

● Twill Weave: Higher strength, can withstand higher differential pressure.

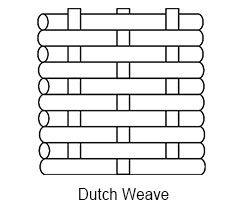

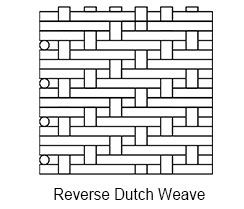

● Dutch Weave / Reverse Dutch: Extremely high filtration accuracy, suitable for precision liquid filtration, catalyst protection, etc.

● Stable pore size, can be fabricated into multi-layer structures

● Enables filtration of extremely fine particles

● High mechanical stability

● Multi-layer metal mesh is vacuum sintered into a single structure.

● Uniform pore size distribution, extremely high structural stability.

● Used in petrochemical, high-temperature reactions, and precision process equipment.

● Slit-type structure, not easily clogged.

● Can withstand high mechanical loads.

● Widely used in water treatment, environmental protection, and continuous solid-liquid separation systems.

● Suitable for coarse filtration, high flow rates, and high-intensity applications, such as mining and metal classification.

● Filter Basket

● Filter Cartridge

● Filter Leaf

● Filter Tubes

● Strainers/Inline Filters (In-line Filters)

Selecting the right filter type is crucial for achieving an optimal balance between high-efficiency filtration, system stability, lifespan, and ease of maintenance. It is a core aspect of industrial filter design and application.

Industrial screen performance is defined by several core parameters—open area, aperture stability, weave structure, wire diameter, and material selection. These factors directly influence flow behavior, filtration accuracy, mechanical strength, and resistance to demanding chemical or thermal environments. Precise control of these parameters is essential to ensure stable system pressure, consistent particle retention, and long service life in critical industrial processes.

| Parameter | Professional Description |

| Mesh Count & Aperture Precision | Defines filtration grade and particle cut-off accuracy. Tight aperture tolerance ensures stable throughput and repeatable separation performance. |

| Wire Diameter & Structural Rigidity | Balances strength and flow. Thicker wires enhance durability under pressure and vibration; finer wires increase open area for higher flow efficiency. |

| Open Area Ratio | Influences flow rate, pressure drop, and energy consumption. Higher open-area designs support high-throughput processes; lower ratios improve mechanical stability. |

| Material Selection & Media Compatibility | Determines corrosion resistance, thermal stability, and chemical compatibility. Ensures longevity and prevents contamination during operation. |

| Weave Type / Screen Structure | Different structures (plain, twill, Dutch weave, sintered mesh, perforated plate) offer unique combinations of strength, permeability, and dirt-holding capacity. |

| Surface Treatment & Cleanability | Treatments such as electropolishing or passivation improve corrosion resistance, reduce particle adhesion, and enhance backwashing efficiency. |

| Mechanical & Thermal Stability | Resistance to pressure shock, thermal cycling, and vibration ensures long service life and minimizes performance fluctuation in demanding environments. |

Recognizing that each application has its own operating conditions, we provide fully engineered, custom-built filtration screens. From mesh count and weave type to advanced alloys and multi-layer constructions, every specification can be tailored to the process requirements. Our technical team supports customers across chemical processing, pharmaceuticals, food production, water treatment, energy, and high-purity manufacturing, delivering filtration solutions optimized for performance, durability, and operational efficiency.

We design and manufacture metal wire mesh for filtration, suitable for solid particles, powders, liquids and gases, to meet the characteristics of different filter media. Each media requires specific pore size control, material selection, and structural strength to ensure stable and efficient performance. With comprehensive customization capabilities, we can precisely design wire mesh for filtration to meet the specific needs of each application.

● Particle Filtration: Precise apertures for consistent particle retention in chemical processing, polymer production, and solid–liquid separation.

● Powder Filtration: Ultra-fine mesh and Dutch weaves for high-accuracy cut-off, suitable for pharmaceuticals, food additives, and metal powder processing.

● Liquid Filtration: Corrosion-resistant materials and stable structures for water, oil, solvents, and process liquids in industrial and food-grade systems.

● Gas & Air Filtration: High open-area meshes for efficient airflow and fine particulate capture in petrochemical, furnace, and ventilation applications.

● Slurry & Viscous Media: Reinforced multi-layer screens for high mechanical stability under pressure and shear, ideal for mining, coatings, and catalyst recovery.

As a leading manufacturer of industrial wire mesh for filtration, we provide precision-engineered screens designed for durability, high performance, and demanding industrial applications. We offer fully customizable mesh specifications, advanced materials (304/316L, duplex, high-nickel alloys, titanium), and multi-layer constructions to suit chemical processing, pharmaceuticals, food production, water treatment, and energy sectors.

Share your requirements, and we’ll provide durable, high-precision screens designed for your process.

Industry

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Related Products

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.